EICC

Electronic Industry Code of Conduct v3.0 1

Version 3.0 (2009)

ELECTRONIC INDUSTRY CODE OF CONDUCT

The Electronic Industry Code of Conduct establishes standards to ensure that working conditions

in the electronics industry supply chain are safe, that workers are treated with respect and dignity,

and that business operations are environmentally responsible.

Considered as part of the electronics industry for purposes of this Code are Original Equipment

Manufacturers (OEMs), Electronic Manufacturing Services (EMS) firms and Original Design

Manufacturers (ODMs) including contracted labor that may design, market, manufacture and/or

provide goods and services that are used to produce electronic goods. The Code may be

voluntarily adopted by any business in the electronics sector and subsequently applied by that

business to its supply chain and subcontractors.

To adopt the Code and become a participant ("Participant"), a business shall declare its support

for the Code and actively pursue conformance to the Code and its standards in accordance with a

management system as set forth in the Code.

For the Code to be successful, Participants must regard the code as a total supply chain

initiative. At a minimum, participants shall also require its next tier suppliers to acknowledge and

implement the Code.

Fundamental to adopting the Code is the understanding that a business, in all of its activities,

must operate in full compliance with the laws, rules and regulations of the countries in which it

operates. The Code encourages Participants to go beyond legal compliance, drawing upon

internationally recognized standards, in order to advance social and environmental responsibility.

The Electronic Industry Citizenship Coalition is committed to obtaining regular input from

stakeholders in the continued development and implementation of the Electronic Industry Code of

Conduct (EICC).

The Code is made up of five sections. Sections A, B, and C outline standards for Labor, Health

and Safety, and the Environment, respectively. Section D outlines the elements of an acceptable

system to manage conformity to this Code. Section E adds standards relating to business ethics.

A. LABOR

Participants are committed to uphold the human rights of workers, and to treat them with dignity

and respect as understood by the international community.

The recognized standards, as set out in the annex, were used as references in preparing the

Code and may be a useful source of additional information.

The labor standards are:

1) Freely Chosen Employment Forced, bonded or indentured labor or involuntary prison labor shall not to be used. All work

will be voluntary, and workers shall be free to leave upon reasonable notice. Workers shall

not be required to hand over government-issued identification, passports or work permits to

the Participant or Labor Agent as a condition of employment.

2) Child Labor Avoidance

Child labor is not to be used in any stage of manufacturing. The term "child" refers to any

person under the age of 15 (or 14 where the law of the country permits), or under the age

for completing compulsory education, or under the minimum age for employment in the

country, whichever is greatest. The use of legitimate workplace apprenticeship programs,

which comply with all laws and regulations, is supported. Workers under the age of 18 shall

not perform work that is likely to jeopardize the health or safety of young workers.

3) Working Hours

Studies of business practices clearly link worker strain to reduced productivity, increased

turnover and increased injury and illness. Workweeks are not to exceed the maximum set

by local law. Further, a workweek should not be more than 60 hours per week, including

overtime, except in emergency or unusual situations. Workers shall be allowed at least

one day off per seven-day week.

4) Wages and Benefits

Compensation paid to workers shall comply with all applicable wage laws, including those

relating to minimum wages, overtime hours and legally mandated benefits. In compliance

with local laws, workers shall be compensated for overtime at pay rates greater than

regular hourly rates. Deductions from wages as a disciplinary measure shall not be

permitted. The basis on which workers are being paid is to be provided in a timely manner

via pay stub or similar documentation.

5) Humane Treatment

The Participant's disciplinary policies and procedures shall be clearly defined and

communicated to workers. There is to be no harsh and inhumane treatment, including any

sexual harassment, sexual abuse, corporal punishment, mental or physical coercion or

verbal abuse of workers: nor is there to be the threat of any such treatment.

6) Non-Discrimination

Participants should be committed to a workforce free of harassment and unlawful

discrimination. Companies shall not engage in discrimination based on race, color, age,

gender, sexual orientation, ethnicity, disability, pregnancy, religion, political affiliation, union

membership or marital status in hiring and employment practices such as promotions,

rewards, and access to training. In addition, workers or potential workers should not be

subjected to medical tests that could be used in a discriminatory way.

7) Freedom of Association

Open communication and direct engagement between workers and management are the

most effective ways to resolve workplace and compensation issues. Participants are to

respect the rights of workers to associate freely, join or not join labor unions, seek

representation, join workers' councils in accordance with local laws. Workers shall be able

to communicate openly with management regarding working conditions without fear of

reprisal, intimidation or harassment.

B. HEALTH and SAFETY

Participants recognize that in addition to minimizing the incidence of work-related injury and

illness, a safe and healthy work environment enhances the quality of products and services,

consistency of production and worker retention and morale. Participants also recognize that

ongoing worker input and education is essential to identifying and solving health and safety

issues in the workplace.

Recognized management systems such as OHSAS 18001 and ILO Guidelines on Occupational

Safety and Health were used as references in preparing the Code and may be a useful source of

additional information.

The health and safety standards are:

1) Occupational Safety

Worker exposure to potential safety hazards (e.g., electrical and other energy sources, fire,

vehicles, and fall hazards) are to be controlled through proper design, engineering and

administrative controls, preventative maintenance and safe work procedures (including

lockout/tagout), and ongoing safety training. Where hazards cannot be adequately

controlled by these means, workers are to be provided with appropriate, well-maintained,

personal protective equipment. Workers shall not be disciplined for raising safety

concerns.

2) Emergency Preparedness

Emergency situations and events are to be identified and assessed, and their impact

minimized by implementing emergency plans and response procedures, including:

emergency reporting, employee notification and evacuation procedures, worker training

and drills, appropriate fire detection and suppression equipment, adequate exit facilities

and recovery plans.

3) Occupational Injury and Illness

Procedures and systems are to be in place to prevent, manage, track and report

occupational injury and illness, including provisions to: a) encourage worker reporting; b)

classify and record injury and illness cases; c) provide necessary medical treatment; d)

investigate cases and implement corrective actions to eliminate their causes; and e)

facilitate return of workers to work.

4) Industrial Hygiene

Worker exposure to chemical, biological and physical agents is to be identified, evaluated,

and controlled. Engineering or administrative controls must be used to control

overexposures. When hazards cannot be adequately controlled by such means, worker

health is to be protected by appropriate personal protective equipment programs.

5) Physically Demanding Work

Worker exposure to the hazards of physically demanding tasks, including manual material

handling and heavy or repetitive lifting, prolonged standing and highly repetitive or forceful

assembly tasks is to be identified, evaluated and controlled.

6) Machine Safeguarding

Production and other machinery is to be evaluated for safety hazards. Physical guards,

interlocks and barriers are to be provided and properly maintained where machinery

presents an injury hazard to workers.

7) Sanitation, Food, and Housing

Workers are to be provided with ready access to clean toilet facilities, potable water and

sanitary food preparation, storage, and eating facilities. Worker dormitories provided by the

Participant or a labor agent are to be maintained clean and safe, and provided with

appropriate emergency egress, hot water for bathing and showering, and adequate heat

and ventilation and reasonable personal space along with reasonable entry and exit

privileges.

C. ENVIRONMENTAL

Participants recognize that environmental responsibility is integral to producing world class

products. In manufacturing operations, adverse effects on the community, environment and

natural resources are to be minimized while safeguarding the health and safety of the public.

Recognized management systems such as ISO 14001, the Eco Management and Audit System

(EMAS) were used as references in preparing the Code and may be a useful source of additional

information.

The environmental standards are:

1) Environmental Permits and Reporting

All required environmental permits (e.g. discharge monitoring), approvals and registrations

are to be obtained, maintained and kept current and their operational and reporting

requirements are to be followed.

2) Pollution Prevention and Resource Reduction

Waste of all types, including water and energy, are to be reduced or eliminated at the

source or by practices such as modifying production, maintenance and facility processes,

materials substitution, conservation, recycling and re-using materials.

3) Hazardous Substances

Chemical and other materials posing a hazard if released to the environment are to be

identified and managed to ensure their safe handling, movement, storage, use, recycling or

reuse and disposal.

4) Wastewater and Solid Waste

Wastewater and solid waste generated from operations, industrial processes and sanitation

facilities are to be characterized, monitored, controlled and treated as required prior to

discharge or disposal.

5) Air Emissions

Air emissions of volatile organic chemicals, aerosols, corrosives, particulates, ozone

depleting chemicals and combustion by-products generated from operations are to be

characterized, monitored, controlled and treated as required prior to discharge.

6) Product Content Restrictions

Participants are to adhere to all applicable laws, regulations and customer requirements

regarding prohibition or restriction of specific substances, including labeling for recycling

and disposal.

D. MANAGEMENT SYSTEM

Participants shall adopt or establish a management system whose scope is related to the content

of this Code. The management system shall be designed to ensure (a) compliance with

applicable laws, regulations and customer requirements related to the participant's operations

and products; (b) conformance with this Code; and (c) identification and mitigation of operational

risks related to this Code. It should also facilitate continual improvement.

The management system should contain the following elements:

1) Company Commitment

Corporate social and environmental responsibility policy statements affirming Participant's

commitment to compliance and continual improvement, endorsed by executive

management.

2) Management Accountability and Responsibility

The Participant clearly identifies company representative[s] responsible for ensuring

implementation of the management systems and associated programs. Senior

management reviews the status of the management system on a regular basis.

3) Legal and Customer Requirements

Identification, monitoring and understanding of applicable laws, regulations and customer

requirements.

4) Risk Assessment and Risk Management

Process to identify the environmental, health and safety and labor practice and ethics risks

associated with Participant's operations. Determination of the relative significance for each

risk and implementation of appropriate procedural and physical controls to control the

identified risks and ensure regulatory compliance.

5) Improvement Objectives

Written performance objectives, targets and implementation plans to improve the

Participant's social and environmental performance, including a periodic assessment of

Participant's performance in achieving those objectives.

6) Training

Programs for training managers and workers to implement Participant's policies,

procedures and improvement objectives and to meet applicable legal and regulatory

requirements.

7) Communication

Process for communicating clear and accurate information about Participant's policies,

practices, expectations and performance to workers, suppliers and customers.

8) Worker Feedback and Participation

Ongoing processes to assess employees' understanding of and obtain feedback on

practices and conditions covered by this Code and to foster continuous improvement.

9) Audits and Assessments

Periodic self-evaluations to ensure conformity to legal and regulatory requirements, the

content of the Code and customer contractual requirements related to social and

environmental responsibility.

10) Corrective Action Process

Process for timely correction of deficiencies identified by internal or external assessments,

inspections, investigations and reviews.

11) Documentation and Records

Creation and maintenance of documents and records to ensure regulatory compliance

and conformity to company requirements along with appropriate confidentiality to protect

privacy.

E. ETHICS

To meet social responsibilities and to achieve success in the marketplace, Participants and their

agents are to uphold the highest standards of ethics including:

1) Business Integrity

The highest standards of integrity are to be expected in all business

interactions. Participants shall prohibit any and all forms of corruption, extortion and

embezzlement. Monitoring and enforcement procedures shall be implemented to ensure

conformance.

2) No Improper Advantage

Bribes or other means of obtaining undue or improper advantage are not to be offered or

accepted.

3) Disclosure of Information

Information regarding business activities, structure, financial situation and performance is

to be disclosed in accordance with applicable regulations and prevailing industry

practices.

4) Intellectual Property

Intellectual property rights are to be respected; transfer of technology and know-how is to

be done in a manner that protects intellectual property rights.

5) Fair Business, Advertising and Competition

Standards of fair business, advertising and competition are to be upheld. Appropriate

means to safeguard customer information must be available.

6) Protection of Identity

Programs that ensure the confidentiality and protection of supplier and employee

whistleblower3 are to be maintained.

REFERENCES

The following standards were used in preparing this Code and may be a useful source of

additional information. The following standards may or may not be endorsed by each Participant.

ILO Code of Practice in Safety and Health

www.ilo.org/public/english/protection/safework/cops/english/download/e000013.pdf

National Fire Protection Agency

www.nfpa.org/catalog/home/AboutNFPA/index.asp

ILO International Labor Standards

www.ilo.org/public/english/standards/norm/whatare/fundam/index.htm

OECD Guidelines for Multinational Enterprises

www.oecd.org

United Nations Convention Against Corruption

www.unodc.org/unodc/en/crime_convention_corruption.html

United Nations Global Compact

www.unglobalcompact.org

Universal Declaration of Human Rights

www.un.org/Overview/rights.html

ISO 14001

www.iso.org

SA 8000

www.cepaa.org/

SAI

www.sa-intl.org

Ethical Trading Initiative

www.ethicaltrade.org/

OHSAS 18001

www.bsi-global.com/index.xalter

Eco Management & Audit System

www.quality.co.uk/emas.htm

The Electronic Industry Code of Conduct was initially developed by a number of companies

engaged in the manufacture of electronics products between June and October 2004. Companies

are invited and encouraged to adopt this code. You may obtain additional information from

www.eicc.info.

![CUBITEK, Inc ]|[ Precision Machine Shop](images/cubilogo.png)

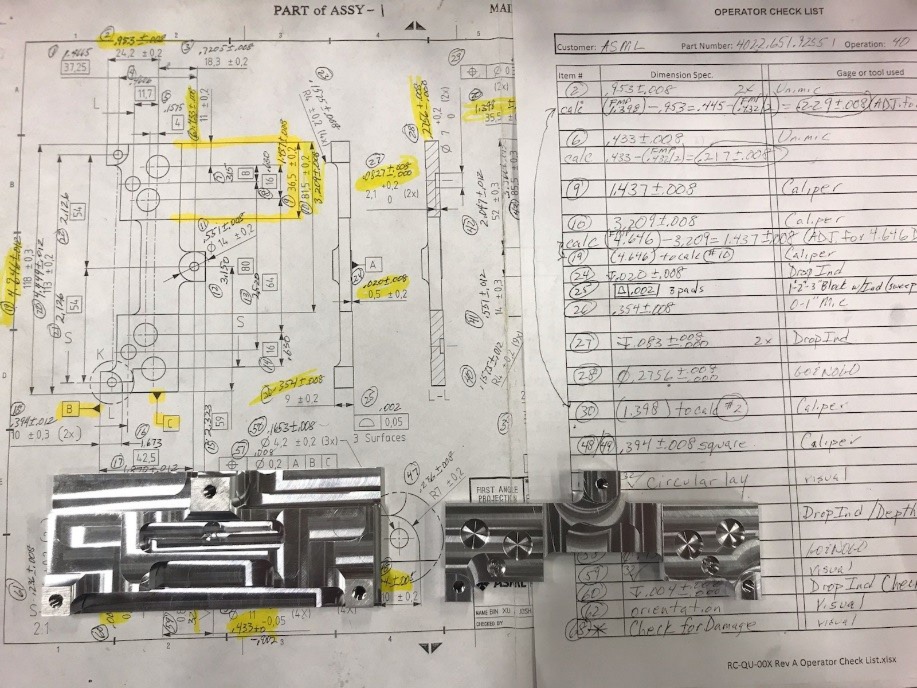

President, Quality Manager Daniel graduated from SUNY Binghamton in 1983 with a degree in Business Management. He is responsible for all final inspections, all outside services, purchasing and sales.

President, Quality Manager Daniel graduated from SUNY Binghamton in 1983 with a degree in Business Management. He is responsible for all final inspections, all outside services, purchasing and sales.

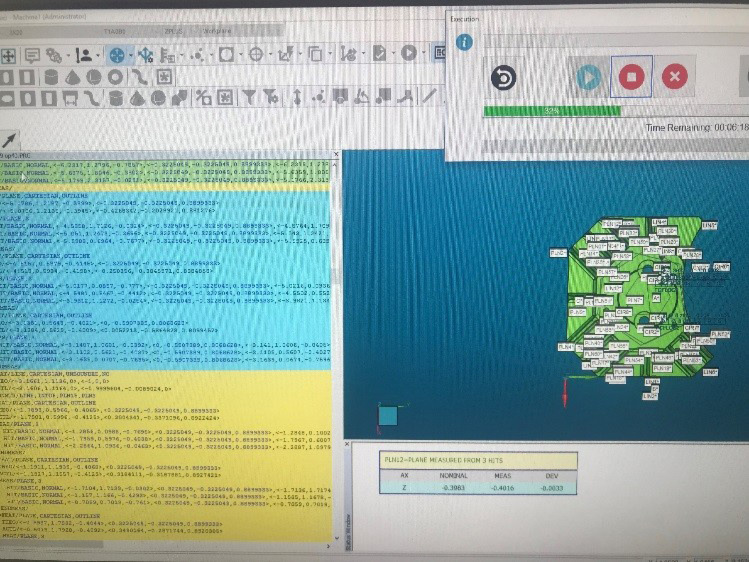

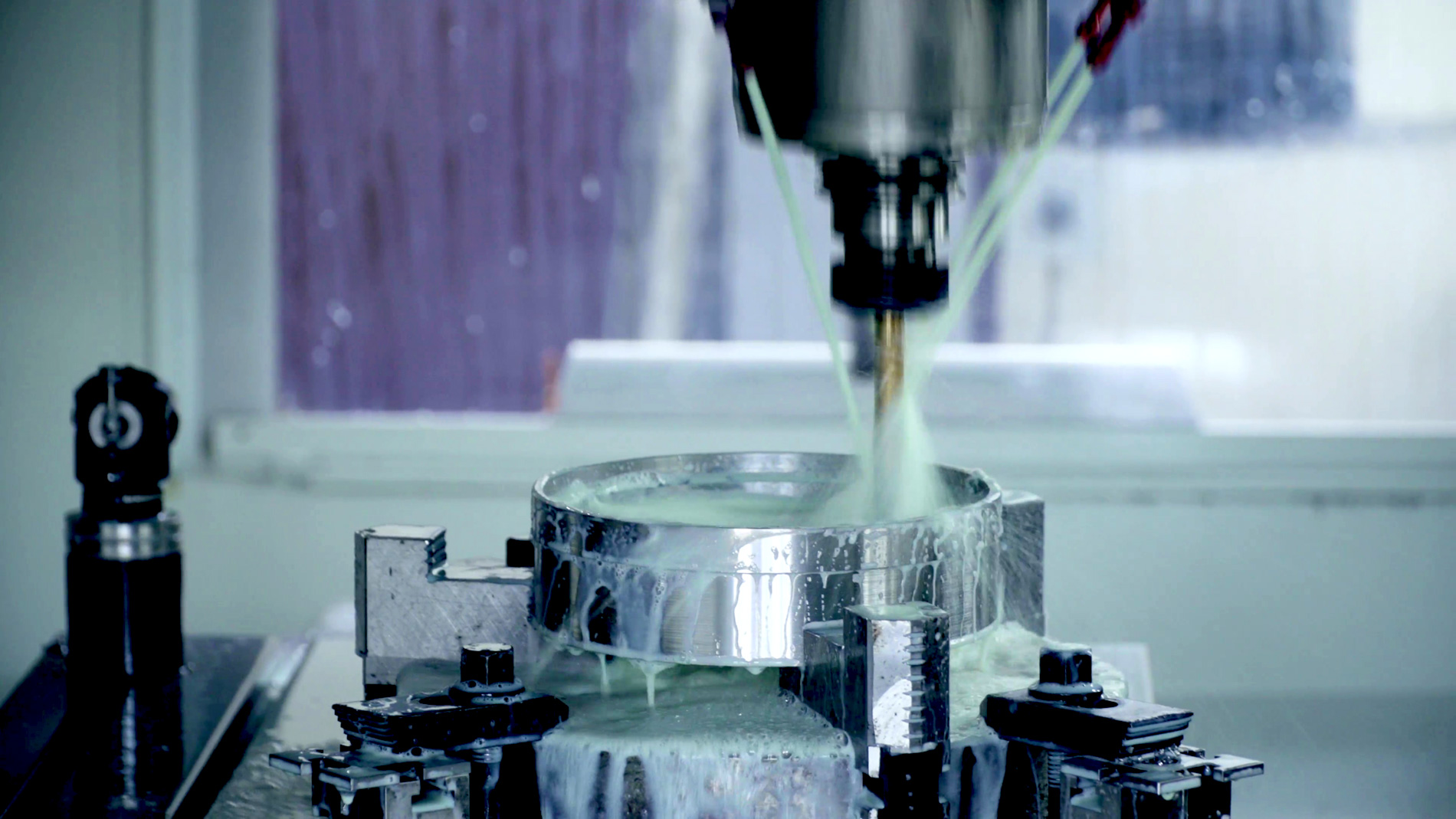

Vice President, Production Manager Peter graduated from Stony Brook University in 1980 with a degree in Biology. He is responsible for methodizing and programming all aspects of each new part, along with machine setup, tooling and supervising the factory.

Vice President, Production Manager Peter graduated from Stony Brook University in 1980 with a degree in Biology. He is responsible for methodizing and programming all aspects of each new part, along with machine setup, tooling and supervising the factory.

Treasurer, Office Manager Judy graduated from Stony Brook University in 1980 with a degree in Psychology and Anthropology. Upon graduation she worked as a Software Engineer for General Instrument Corporation until 1987 when she left to become a full time mom. Once the little ones started nursery school, Judy began working from home for AES-Group as a purchasing agent of spare parts to support the Royal Thai Airforce and Navy. She gave that up in 2003 to work full time for Cubitek. Judy is responsible for all areas of accounting, order entry, reviewing open orders and customer service.

Treasurer, Office Manager Judy graduated from Stony Brook University in 1980 with a degree in Psychology and Anthropology. Upon graduation she worked as a Software Engineer for General Instrument Corporation until 1987 when she left to become a full time mom. Once the little ones started nursery school, Judy began working from home for AES-Group as a purchasing agent of spare parts to support the Royal Thai Airforce and Navy. She gave that up in 2003 to work full time for Cubitek. Judy is responsible for all areas of accounting, order entry, reviewing open orders and customer service.

Ethan graduated from SUNY Geneseo in 2011 with a degree in Business and International Relations. He has worked summers and school breaks since he was a teenager and finished his MBA full time at Baruch College in Manhattan in 2018. Ethan and has taken on all production planning and scheduling.

Ethan graduated from SUNY Geneseo in 2011 with a degree in Business and International Relations. He has worked summers and school breaks since he was a teenager and finished his MBA full time at Baruch College in Manhattan in 2018. Ethan and has taken on all production planning and scheduling.